Crafting a Greener Pint Starts with Energy Reduction

A Sustainable Brew

In the heart of the UK’s brewing industry, an energy shift is taking place. With the global push towards sustainability and rising energy costs, breweries are finding themselves at a crossroads: how can they continue producing the beloved pint while significantly reducing their environmental footprint? This question isn’t just rhetorical—it’s a call to action for every brewery aiming to thrive in an increasingly expensive and eco-conscious market.

From Watts to Hops

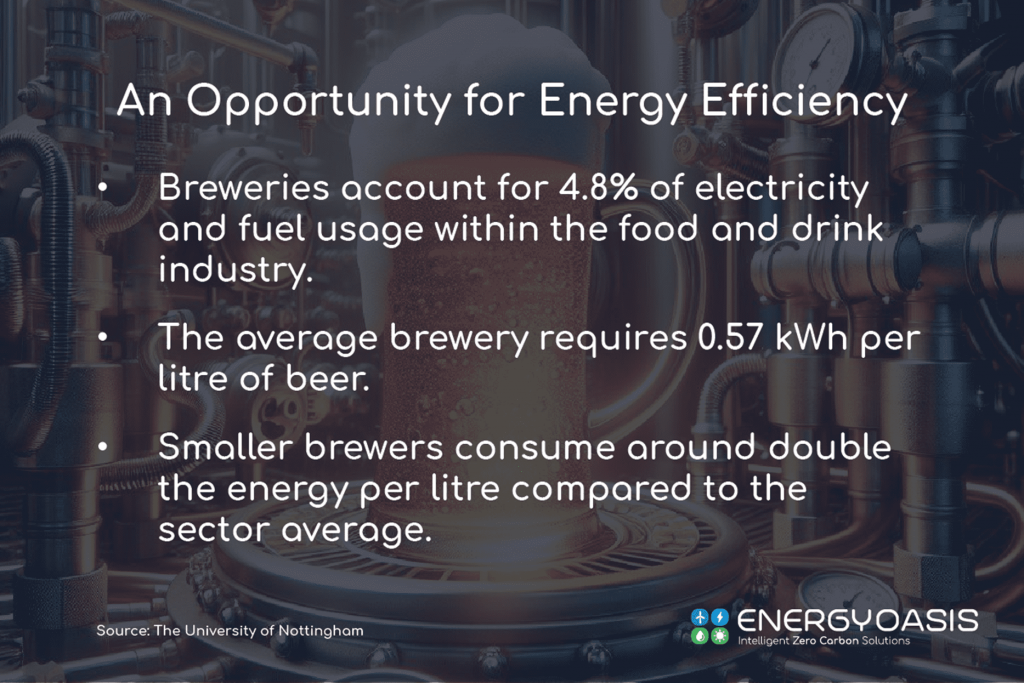

Consider this: the brewing process is notoriously energy-intensive, demanding substantial amounts of water, heat, and cooling. Breweries contribute significantly to industrial energy usage, with energy expenses constituting a notable portion of production costs. Research from the University of Nottingham reveals that smaller breweries consume approximately double the energy per litre of product compared to the average in the brewing sector.

This situation presents not just a challenge, but also a promising opportunity for saving. The Carbon Trust projected a 5% reduction in carbon emissions, equivalent to 22,000 tonnes of CO2 per year, within the brewing industry by adopting energy-efficient practices.

Crafting Success

The movement towards sustainable brewing is gaining momentum, not just as a niche trend, but as a fundamental shift in how breweries operate and strategise for the future. So, how can your brewery join this green revolution? Well consider that the greenest and cheapest kilowatt is the one you don’t use! So it all starts with reduction, whether that’s implementing energy-efficient lighting, upgrading to more efficient refrigeration systems, and exploring heat recovery technologies. Each of these steps not only contributes to a healthier planet but also to healthier profit margins through reduced operational costs.

The transition to renewable energy sources such as solar, wind, and biomass becomes more realistic and affordable for small to medium size breweries if energy demands are lower. It is not just about reducing carbon footprints; it’s also about crafting a brand identity that resonates with today’s environmentally conscious consumers. Before investing in renewable technology to meet your energy needs, first consider reducing your energy needs. The path to Net Zero doesn’t need to cost the earth.

Your Next Steps

The path towards a greener pint is clear, but it requires action. Begin by assessing your brewery’s current energy use and explore the myriad of sustainable technologies available. Working with an energy management specialist such as Energy Oasis, engaging with experts who can guide you through the transition to more efficient and renewable energy sources will help plot an affordable path to Net Zero.

As we look to the future, the question isn’t whether we can afford to invest in energy efficiency—it’s whether we can afford not to. The benefits, both environmental and financial, are too significant to ignore. Let’s work together to brew a better future. The time to act is now.